Heel Kerb

Specifications:-

Raw Materials and Resourses

Cement:

The cement used in manufacturing of kerb stone is type SRC, in accordance with ASTMC 150. The content of the cement is 400kg per Cu. M minimum.

Aggregates:The aggregates used in the manufacturing of kerb stones are from crushed rocks and from approved sources. Washed sand conforming the requirements of BS882 is used and is free from harmful substances such as coal, mica, clay etc. Coarse aggregates and fine aggregates are used as per BS812 standard in definite proporations to get maximum density of the block. The ratio generally falls between 1.3 Coarse to fine aggregates. Water absorption for coarse aggregates shall be maximum 1.5% and for fine aggregates shall be 2.5%.

Water: The water used for producing and for curing of kerb stones is potable drinking water, supplied by local municipal authorities, and is free from salts and silicates.

Curing: The curing of the kerb-stones is with potable water for at least 3 to 7 days for optimum strength.

Aggregates:The aggregates used in the manufacturing of kerb stones are from crushed rocks and from approved sources. Washed sand conforming the requirements of BS882 is used and is free from harmful substances such as coal, mica, clay etc. Coarse aggregates and fine aggregates are used as per BS812 standard in definite proporations to get maximum density of the block. The ratio generally falls between 1.3 Coarse to fine aggregates. Water absorption for coarse aggregates shall be maximum 1.5% and for fine aggregates shall be 2.5%.

Water: The water used for producing and for curing of kerb stones is potable drinking water, supplied by local municipal authorities, and is free from salts and silicates.

Curing: The curing of the kerb-stones is with potable water for at least 3 to 7 days for optimum strength.

Physical and Mechanical Properties

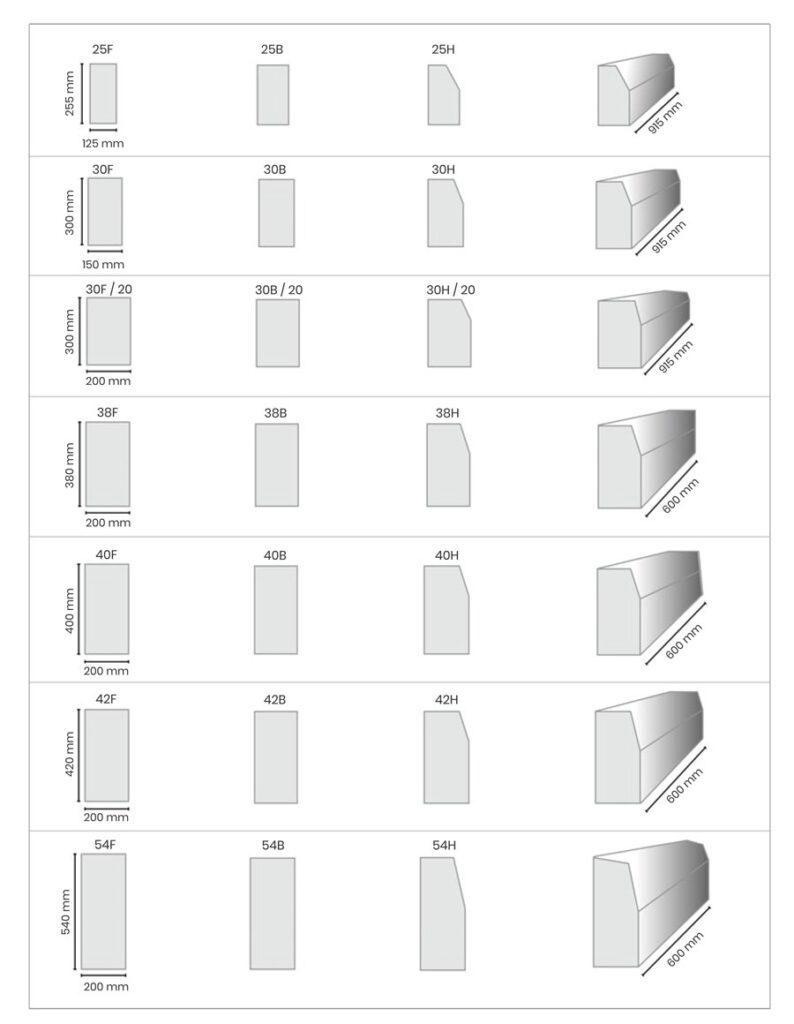

Transverse Strength: The transverse strength of the kerb stones as per Bs7263, part 1, 1994 for the size 125*250*915, shall be minimum 12.9 KN for span of 750 mm and size 150*300*925 shall be minimum 20.9 KN. Depending upon the size and thickness of the stones, the transverse strength will vary.

Dimentional Tolerance:

The thickness variations of the kerb stones shall not exceed 5 mm an height and length variation shall not exceed 2 mm.